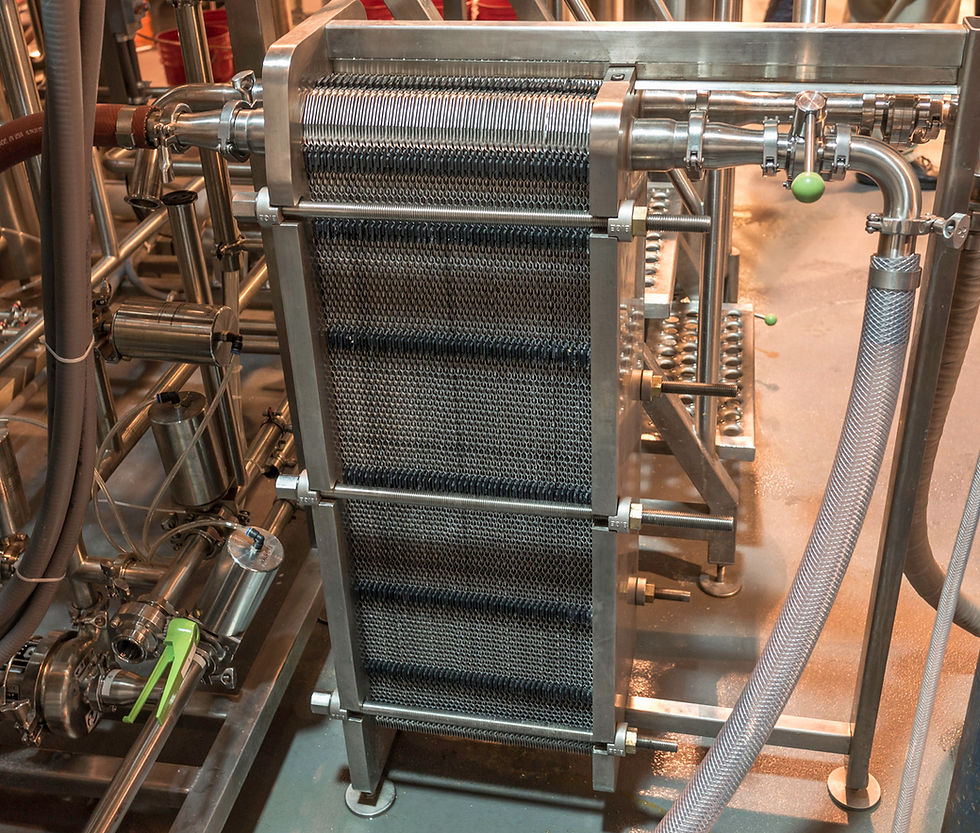

Plate and Frame Heat Exchangers

- MSC

- Aug 22, 2022

- 2 min read

Updated: Sep 21, 2022

A heat exchanger is a system used to transfer heat between two fluids, either liquid or gas, without the media coming in contact or mixing. The plate and frame heat exchanger uses a series of thin corrugated metal plates separated by gaskets to transfer heat between media flowing through alternating chambers. The large surface area of the plates and the narrowness of each chamber maximize the exchange of heat. Plate and frame heat exchangers are well-suited for heating fluids of low to medium viscosity.

Though plate and frame heat exchangers are silent and have no moving parts, proper maintenance is a necessity. Narrow gaps between the plates tend to trap foreign matter, which can lead to clogging, fouling, and scaling. If buildup is allowed to accumulate on the plates, their surfaces will have less direct contact with fluids and the exchange of heat will be decreased. Forcing the fluids through a smaller space can lead to pressure drop, which increases energy consumption and puts stress on the overall system. Gaskets should be inspected regularly for failure, and plates should be checked for cracks that can cause cross-contamination between fluids.

If fouling, clogging, or scaling is a recurring problem, it’s important to identify and correct the underlying causes. Poor water quality is a large contributor, so plate and frame heat exchangers should always be equipped with adequate filtration, particularly when connected to an open loop. Sensors or gauges should be used at inlet and outlet ports to track performance and monitor for unexpected temperature or pressure changes. Instrument accuracy should be checked at least once a year, and proper flow rate should be verified on a regular basis, even on new, clean systems.

Preventive maintenance for plate and frame heat exchangers is minimal compared to other types of equipment and relatively simple to perform. Units should be back-flushed regularly and visually inspected for leaks. Gaskets should be checked for brittleness. A mechanical cleaning should be performed every few years, depending on the condition of the water and frequency of back flushing. Change gaskets every five to ten years, and plates should be cleaned and reconditioned by the manufacturer or other authorized company every ten to fifteen years.

Comments